Relied On Lift Maintenance Repair Solutions for Reliable Operation

Wiki Article

Unlocking the Tricks to Effective Lift Repairs: Expert Insights Revealed

In the realm of lift repair and upkeep, revealing the techniques that bring about reliable and efficient solution belongs to decoding an intricate challenge. Expert insights function as the leading light through the labyrinth of obstacles encountered by upkeep professionals in the upright transport market. By delving into the midsts of proactive strategies, troubleshooting strategies, and the continual quest of ability enhancement, the path to boosting maintenance criteria exposes itself. As we embark on this trip to demystify the secrets behind structured lift repair work, a globe of possibilities arises, guaranteeing a future where downtime is reduced, safety and security is prioritized, and operational excellence comes to be the norm.Common Lift Repair Service Obstacles

One more common challenge in lift repairs is the lack of correct upkeep documents. Without precise upkeep documents, repair specialists may battle to detect problems efficiently or anticipate potential troubles. This can cause longer repair service times and enhanced costs as professionals function to fix concerns without historic data to lead them.

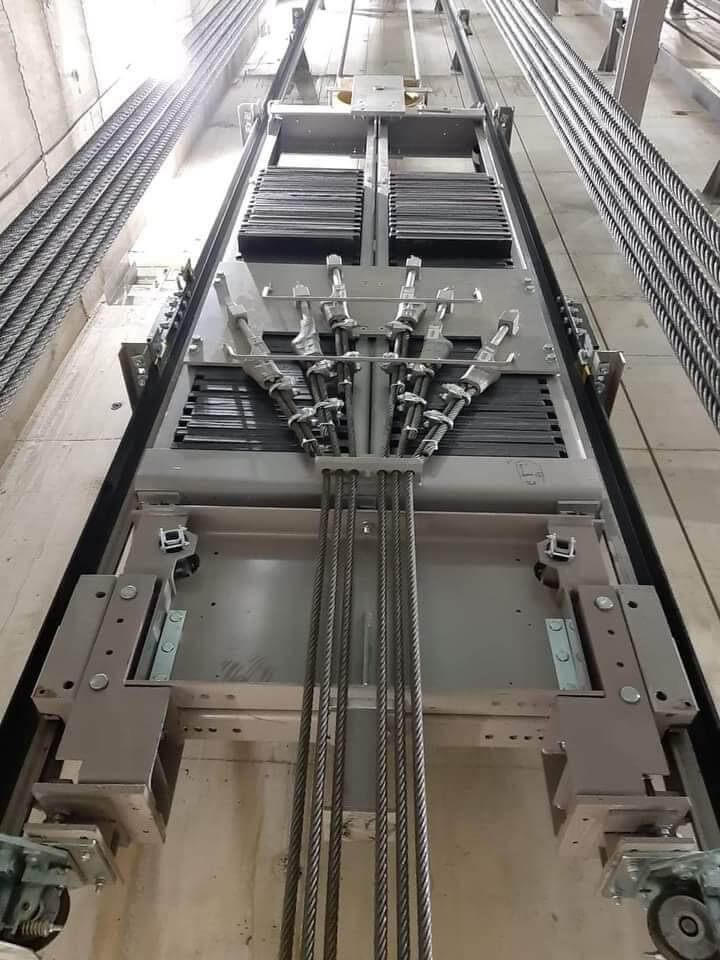

In addition, availability issues within lift shafts can posture considerable challenges throughout repair work. Limited room, uncomfortable angles, and intricate machinery can make it difficult for professionals to get to the required parts for repair service work, extending the overall fixing procedure - Lift Maintenance Repair. By dealing with these usual challenges proactively, lift fixing experts can boost operational performance and guarantee the smooth performance of vertical transport systems

Proactive Upkeep Techniques

Implementing positive upkeep strategies is vital for ensuring the durability and optimum performance of lift systems. By embracing a proactive strategy to maintenance, building managers and lift upkeep teams can address prospective problems before they rise into expensive fixings or downtime. One effective method is to develop a normal maintenance timetable that consists of extensive examinations, lubrication of relocating parts, and testing of safety functions.

Furthermore, buying training programs for maintenance personnel can improve their skills in determining prospective issues and carrying out precautionary upkeep jobs effectively - Lift Maintenance Repair. By encouraging upkeep groups with the expertise and devices needed to proactively maintain lift systems, structure proprietors can lessen interruptions, prolong the lifespan of their lifts, and ensure a safe and dependable vertical transport experience for passengers

Fixing Methods

Effective troubleshooting methods are essential for immediately determining and dealing with problems great post to read with lift systems to lessen downtime and make sure optimal performance. One reliable strategy is to begin with a comprehensive aesthetic examination of the lift components, inspecting for any kind of visible indicators of wear, misalignment, or damages.

Enhancing Repair Skills

Enhancing proficiency in lift system repairs is a basic element of guaranteeing optimal capability and reducing operational disturbances. Lift service technicians must continually work with refining their repair work abilities to meet the needs of contemporary lift systems. One crucial method for enhancing fixing abilities is routine training sessions that concentrate on both academic knowledge and sensible application. These sessions can cover a series of topics such as brand-new innovations in the industry, repairing complex concerns, and safety methods. In addition, service technicians can benefit from hands-on experience under the advice of experienced specialists to enhance their analytic abilities and decision-making skills in real-time repair situations.Furthermore, staying updated with the most recent advancements in lift innovation is vital for technicians wanting to improve their repair service abilities. This entails proactively inquiring about new elements, software application updates, and upkeep strategies to properly detect and rectify issues. By spending time and effort right into continual learning and sensible experience, lift professionals can significantly boost their repair competencies and contribute to the reliable performance of lift systems.

Boosting Upkeep Specifications

Raising maintenance standards in lift systems is vital for making sure long term functional effectiveness and security. Regular maintenance not just improves the performance of lift systems but also decreases the threat of unforeseen break downs and guarantees the safety of customers. By sticking to strict upkeep procedures, lift proprietors and drivers can considerably reduce the chance of expensive repair work and downtime.Implementing a thorough maintenance schedule that includes regular examinations, lubrication of moving parts, and positive replacement of used components is crucial. Using advanced modern technologies like IoT sensing units and predictive upkeep software can assist in keeping track of the lift's problem in real-time, allowing prompt interventions prior to problems rise. Furthermore, providing constant training for upkeep personnel on the most recent market standards and finest techniques is necessary for websites upholding upkeep excellence.

Moreover, cultivating a culture of accountability and interest to information among maintenance teams can further elevate maintenance requirements. Urging open communication channels for reporting and resolving maintenance issues immediately can aid in maintaining a high level of lift system reliability. Eventually, by prioritizing and raising upkeep criteria, lift systems can operate efficiently and safely for an extended period.

Conclusion

To conclude, reliable lift repairs require proactive maintenance strategies, troubleshooting techniques, and enhanced repair abilities. By boosting and attending to typical difficulties maintenance standards, maintenance specialists can properly make certain the smooth procedure of lifts - Lift Maintenance Repair. Carrying out these professional insights can lead to boosted performance, minimized downtime, and enhanced safety for both passengers and toolsIn the realm of lift repair work and maintenance, revealing the methods that lead to reliable and efficient solution is similar to analyzing a complex problem.One more prevalent obstacle in lift repair services is the lack of correct upkeep documents. By adopting an aggressive technique to maintenance, structure managers and lift upkeep teams can attend to prospective problems before they intensify into expensive repairs or downtime.In verdict, Check Out Your URL efficient lift fixings require aggressive maintenance strategies, repairing methods, and enhanced repair service skills. By attending to common difficulties and boosting maintenance criteria, upkeep experts can properly guarantee the smooth procedure of lifts.

Report this wiki page